|

|

|

|

Detailed instructions

for making the

Butterfly Bean Bag

|

This

is essentially a simple project, however, explaining how to

go about it is a bit more complex than the actual project.

In truth,

the writing of this set of instructions took three times longer

than it took to cut and sew these bean bags. Mostly the hard

part is explaining

how to sew the back-to-back technique. This design is based

on a design from an article

by Scott Fairbairn.

The instructions on how to sew the double bean bag design

seem a bit fuzzy. It took some head scratching

to figure out how to do it the first time I tried it. Without

a good sense

of three-dimensional space, it can almost seem like a magic

trick when you see it done. However, I will attempt to take

the mystery

out of it and make it seem nearly as simple as it actually

is.

User

Emails and Comments on the bean bag project:

Proof it's not so hard to make - Malaysian

nature photographer Dr. A. R. Radzian shows off

his version of the Butterfly Bean Bag

--- Photo

one (materials and printed pattern) ----

Photo

Two (finished bean bag) --- link

to full blog entry of June 2009 (scroll way

down ) --- Dr. Radzian wrote: "I know a few

of my friends also made the similar bean bag when

I posted it at PhotoMalaysia.com."

Tested, reviewed and approved on safari - Gets

highest rating - On the "Chobe Safari"

website, for Chobe National Park in Botswana, author

and photographer P. B. Eleazer tested 21 commercial

and DIY bean bags and rated them in his web article

( http://www.chobesafari.com/photography-tips/finding-the-perfect-photo-bean-bag-for-safari.html

). I was pleased to find that my bean bag design

received his highest rating along with two expensive

commercial bean bags. In fact, he made two of my

design for himself. Now that brought a smile to

my face.

Here's another photographer's take on my

Butterfly Beanbag. Roy Bertalotto posted his version

of my beanbag design on

his blog.

Butterfly Beanbag survives Hyena mauling ...

some beans did not - Received this fun

report from Mary Anne A. who made the Butterfly

Beanbag for her Tanzania/Serengeti safari. |

|

Reference

image -

click for larger view |

Step #1- Print the pattern onto

paper so you can transfer it to the material.

For this you will need the pattern files and a printer.

The pattern is in two resolutions. Use this file

at 72 dpi to view on your monitor for reference. The pattern at 150 dpi for

printing on your printer comes in four parts because the pattern is slightly larger

than 11x17. It has to be printed on four pieces of 8 1/2x11 paper, then overlapped

to match up each section and taped together to make the full-sized pattern. Do not

print the 72 dpi file meant for viewing. It will NOT print to actual size, and you

will end up with a rather tiny and useless bean bag. So, save each of the four files

below to your computer and print each on a standard letter sized sheet, or you could

print them right from your browser. Just be sure the actual image area of

each section measures 8x10 inches when printed. Once you assemble the four printouts,

the white part of the pattern should just fit in an 11x17 space (the gray outside

area will be a bit larger than that). If

this is not the case when you've printed and assembled them, then the software program you are printing from is resizing them somehow

and

the

pattern

will

not be

the correct size. This is not to say you can't alter the size to suit your needs, but generally this would be as large as you should need.

Pattern

section one

Pattern

section two

Pattern

section three

Pattern

section four

Now, assemble the four printouts, carefully overlapping

and aligning the images so they match up, then tape the four sheets together into

one large pattern. Now, cut out the paper pattern on the solid outline, which will

remove the outer gray shaded edges. There are further instructions printed right

on the pattern explaining the various dotted lines. Pay attention to those instructions.

Step #2- Cut out the two gray shaded

parts of the rectangle, and cut out the small "V" shaped gray area

as instructed on the pattern.

DO NOT cut these holes in the material, only cut them

on the paper pattern. They are there to help you transfer the pattern to the material

when that step comes.

Step #3- Transfer the pattern to

the material.

(a) In this step

you first will cut four identical rectangular pieces of material about two

inches larger than the length and width of the paper pattern, which should give you

four rectangles about 13x19 inches each. This extra room will allow for error and

for the seams. If your material has a printed-on pattern (as opposed to a woven pattern),

one side of the material will have the full color pattern, and the other side will

either be blank or will show only a faded bleed-through of the pattern. In this case

the material has a distinct front and back side.

(b) Next, stack

and align the edges of the four basic rectangles you've cut out. Stack them so that

you have two front sides facing up and two back sides facing up. The order doesn't

matter so long as one of the pieces with the back side facing up is on top of the

stack so you can trace the pattern onto it. It will be easier to see your tracing

on the back side of a piece than on the side with a strong printed pattern.

(c) Now pin these

four aligned and stacked pieces together so they will not shift.

(d) Next, center

the paper pattern on the top of the stack and pin it in place with at least two pins

so it will not shift. The idea here will be to cut out 4 identical pieces at the

same time from one traced pattern. (Alternately, you could trace and cut out all

four pieces individually if you preferred.)

(e) Now it's time

to trace the outer edge of the pattern onto the material. I used a ball point

ink pen to do this, but you may have a better method, such as a fabric marking pencil,

which would be good if your material is dark. Note: You will NOT cut on this outline

you just traced.

(f) With the pattern

still pinned in place, go back and draw another outline around the pattern spaced

about a half inch outside the paper pattern edge. This doesn't have to be perfect

since it will be inside the finished bean bag and will not be seen, but you will

need this extra half inch or so of material for the seam. The inner outline that

conforms exactly to the pattern is where you will stitch the pieces together,

following the line and stitching right over it. This second outer outline will

be the one you actually cut the material on.

(g) There is one

more tracing operation to do before any cutting can be done. Remember the two ends

of the rectangle you cut out of the paper pattern? Now you are ready to take advantage

of that. The pattern is still pinned in place, so you should trace around the edge

of the rectangle. Only the straight edges need be traced. You do NOT need to trace

the curved edge of the elongated "football" shape now. That is for something else.

Now you can unpin and remove the paper pattern. Lay

it aside for later as you will need it again. You will note there is a gap at the

top and bottom of the rectangle you just traced where the "football" shape area was

in the way. Just for good measure, take your ballpoint and fill in this part of the

line to complete marking in the whole rectangle. Now it's time to unpin the four

pieces of material and separate them, but keep whichever side was facing up still

facing up on each piece.

From now on I will refer to the printed pattern side of

the material as the "outside", and the non-printed side as the "inside".

If your material is a woven pattern, or simply a solid color, and

both sides are exactly the same, this part of my instructions won't

make any difference. But if you use a camo material as I did, you

don't want the pale/blank side out, you want the camo side out,

so pay attention to which side is which.

Step #4- Sewing the rectangle

You're almost ready to do a little sewing. This is

the easiest part. Take the pattern piece you just marked the rectangle on and place

it on top of another pattern piece so that the two "outsides" are facing each other.

Align their edges and pin them together around the edges, and also near the rectangle

outline. You should now have two cut pieces pinned together with the "insides" facing

out both ways when you flip it over. You are now ready to "join" the two bean bags

back to back before you even sew the two bags themselves. It might seem illogical,

but I assure you, this is the only way it can be done, and is part of the "magic".

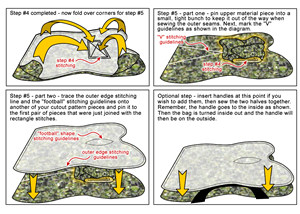

Refer to the first box in the Diagram

for Steps #4 and #5 below to see the two pieces facing each other and stitched

along the rectangle. This is what you will be doing.

I will note here that unless

you use a pretty heavy-duty material, you might want to reinforce this rectangular

area where the two bags join. On mine, I cut two rectangles of fabric about a half

inch larger all the way around than the rectangle. Then I used a ruler to extend

the rectangle's lines outside the rectangle. I pinned the reinforcing material centered

over the rectangle and then used the lines I added as a guide to transfer the rectangular

marking back onto the reinforcing piece using my pen and a ruler. I did this for

both pieces of material. Remember, this will end up "inside" the bean bag and won't

show.

Okay, fire up the sewing machine and sew along

the rectangle outline, stitching directly over the line all around the rectangle.

Then do it again, this time stitching inside the rectangle about 1/8 of an inch to

create two seams side by side all the way around. Then stitch an "X" from corner

to corner inside the rectangle. DO NOT SEW THE OUTSIDE EDGES OF THE MATERIAL,

sew ONLY in the rectangle. Okay - you are now basically 1/3 finished.

| Diagram

for Steps #4 and #5 |

|

Click

this diagram for a larger view

of the directions. |

Step

#5- Preparing to complete one of the bean bags

Look over the Diagram

for Steps #4 and #5 again. Now you will fold over the top material piece,

overlapping the four "corners" and folding them into a small, tight bunch over the

rectangular area you just stitched. Now pin this "bunched" material together to keep

it out of your way. You need to do this so it does not get caught in the outer edge

stitching in the next step.

Next you take another of the cutout pieces and turn

it with the "inside" facing up. Place the paper pattern on top of this piece, center

the pattern and pin it so it won't slip. Now trace around the outer edge with your

ink pen (or fabric pencil) as you did before. This will provide you the outer sewing

line, leaving the 1/2 inch of seam area as before. With the pattern still pinned

in place, trace the "football" shaped guidelines onto this piece of material.

To accomplish this, trace around the "football" shaped

area inside the rectangle. Now note the two "reference points" C and D printed on

the pattern. If you like, you can poke a hole in the paper pattern at reference points

C and D and make a mark or dot on the material so you can find these points. Now

remove the paper pattern and fill in the missing parts of the "football" shape guidelines.

Next you need to trace the "V" sewing guidelines onto

the other half of this bean bag (refer again to the Diagram

for Steps #4 and #5). Line up the lower end of the paper pattern and make

a mark at the outer edge of the material at reference points A and B where the dashed

sewing guidelines meet the outer edge. Now trace inside the small triangular cutout

hole you made in the paper pattern. This now provides you with the "V" point and

the two ends of these lines, and you can use a ruler to finish connecting these ends

to complete the "V" guidelines. For the time being this will be covered and sewn

inside the bag, but you will use this "V" guideline later. If you have nylon webbing

straps or other material to use for handles, get that out and have it ready. I made

my handles from the same material as the bean bag.

Now you must align the two pieces that you've added

the guidelines to as shown in the diagram box labeled "Step #5- part two". At this

point you should insert any handles you desire as shown in the "Optional step" box

of the diagram. Now pin the two pieces together around the outer edge, and be sure

the handles are pinned as well. Insure the ends of the handles hang across the stitching

area so they will be caught by the outer stitching. Okay, it's time to sew again.

|

| Diagram

for Step #6 |

Step

#6- Sewing the first bean bag

Stitch

around the outer edge of the bean bag, following and stitching

right on the line you traced a half inch in from the material

edge, but DO NOT stitch all the way around. Leave

a section about three to four inches long unstitched near

the top of the bag. This is where you will turn the finished

bag inside out, and it's also where you will pour in the

beans. (Optionally you might wish to sew in a zipper

in this area instead of leaving an opening that will need

stitching by hand later to close it. I couldn't find

a zipper shorter than 7 inches, which I felt was too long,

so I opted for the more permanent hand stitched closure.)

When you get to the handle ends, stitch across them

two or three times between the guideline and the edge of the material for strength.

It would even be a good idea to lay a strip of material along the edge on both sides

of the bag, stretching across the handle ends to "double up" on the material thickness

and reinforce it. I didn't do this, but it's still a good idea. Be especially

careful at the "top" of the bag where the upper "corners" dip down in the middle.

There isn't much space between the "dip" and the rectanglar stitching area where

all the material is folded up and pinned. If you happen to catch some of that material

in the stitching, you will NOT be able to turn the finished bag inside out.

Now that you've stitched all

around the edge (except for the 3-4 inch opening), there is one more bit if stitching

to do. Look at the "Diagram for Step

#6" . It shows how to pinch together the material where the "football" shaped

guidelines are, squeezing them together and stitching them. Be sure you do NOT catch

anything from inside the bag in this stitching. This stitching will have the effect

of drawing the upper part of the bag tighter and making it stand taller without bulging

and flopping. This flap of material you've created will be on the inside of the bag,

so it's not seen. There is no need to cut it off. If you do cut it, and

the stitches should come out, you would have a hole in your bag!

|

The

tubular bottom design improves rigidity and cuts

the weight by 4 pounds.

|

Time to take out your pins, then pull the inside bundle of pinned fabric to the opening and take out those pins as well. Now you can patiently work the finished half of the bag inside out, pulling a bit at a time until you have it all pulled through the opening. You will find that you now magically have one finished bean bag attached to half of the other bean bag yet to be sewn. You are now 2/3 finished.

It's

time to do the other bag. The great part about this

is that I don't have to write more instructions. You only

need to go back to Step #5 and follow the instructions

all over again to complete the other side of the project.

Fold up and bundle the finished bag and pin it over the

rectangular area as before, mark the guidelines for the

"V", for the "football" shape area, and the outer guidelines

on your last piece of material, then insert the handle,

pin it all together, and sew. When done, remove the pins

and turn it inside out, and you will have two bean bags

attached back to back.

Step #7- One last bit of stitching

Now

it's time to stitch those "V's" you traced onto the outside

of both bags. Don't sew the two bags together now and

ruin your project. Each bag has a "V" sewn into it to

connect the two halves of each bag as clearly shown in

the photo

at the left. This is the real secret to this design,

though it's not much of a secret now. Once you've sewn

these two "V's", you can fill the bags with beans or other

filler material and stitch the opening shut. Voila. You're

done.

|

| |

|

|

|

|

|