|

|

|

|

Super-telephoto Folding Lens Hood

and a different lens cap

|

|

Folding

hood and new lens cap

for a Canon 500mm f/4L IS |

Yep...this

is another project to make something for my 500mm lens.

Actually it's two somethings... a folding lens hood, and

a protective lens cap (more about the lens cap in a bit).

The idea of a collapsible folding lens hood was not mine...well,

what I mean is, I didn't think of it first. There is the

"TravelHood" made by LensCoat, and AquaTech makes their

"Soft Hood" product. I wasn't aware of either product

until I heard about the "TravelHood" on a photography

forum and checked it out. It is actually a good idea....

a hood that will fold flat and save space. And for $110-$150

either product is a much cheaper alternative to replacing

a damaged or lost Canon 500mm hood than getting another

Canon hood for well over $500.

|

Mounted

to the lens is the original

Canon hard hood with my DIY camo cover.

Next to it is my new DIY folding hood

|

Though

my hood did not need replacing, I had for some time been

hoping to find a way to more easily fit my 500mm lens

into my Bataflae 32L backpack. If I didn't have to carry

it with that huge hood, it would fit much better. A folding

hood sounded like an ideal solution. But once again, I

ran up against that wall that separates my wants from

my wallet. Am I REALLY going to pay $110-$150 for something

I can easily make with less than $10 worth of fabric and

a sewing machine? Yeah, well, you already know the answer

to that question. Heck, you could buy the material AND

a brand new basic sewing machine for less than $150. Let's

get real, folks.

The

general concept is very simple - flat slats sewn between

an outer camo material and an inner non-reflective black

material, which then wraps around the lens to form a hood.

The slats must be stiff, yet flexible while being strong

and unbreakable, and completely waterproof. The LensCoat

"TravelHood" uses velcro straps to hold it into shape,

while the AquaTech "Soft Hood" uses buckled straps. Frankly,

the buckled straps appeared to be overkill (and awkward)

for a lightweight hood, and the LensCoat hood's huge velcro

straps gave it an unfinished, "slapped together" apperance.

I had a better and cleaner-looking idea in mind for attaching

my folding hood. Both products appear to be made from

nylon or polyester Cordura type fabric that is water repellant

and sturdy. I already had some remnants of 600 denier

polyester Cordura camo fabric on hand, the same as I've

used for so many of my other projects. All I had to do

was figure out what to use for the slats.

|

The

first assembly - pockets with

the vinyl slats inserted

|

With

a bit of head-scratching, I finallly remembered some vinyl

strips I had in the garage. I had recently put vinyl leaf

guards on my rain gutters, but the guards were a little

wide for my gutters. So I trimmed 1-1/2 inches off one

edge on all of the leaf guard sections to fit better.

It turned out those leftover strips, just under 1/16 inch

thick, were exactly what I needed - waterproof, very flexible,

yet stiff enough in 9-inch lengths to spring right back

into shape when bent. It would work perfectly for the

slats. The width (1-1/2 inches) was just right

as is. I cut 13 pieces about 8-1/2 inches long and smoothed

any rough edges. Your project may take different lengths

or a different number of slats, but for my 500mm I calculated

that 13 x 1-1/2 inches would do the trick.

First Assembly - Hood Slats:

After

taking measurements of my lens and the original hard hood,

I cut some Cordura camo and black ripstop nylon material

25-inches by 9-1/2 inches for the new folding hood (yours

doesn't have to be camo). Both measurements are oversized

to allow for hems and flaps for velcro (particularly

on both ends where it wraps around into a cylinder).

I sewed the Cordura camo face to face onto the ripstop

nylon around three edges (one long side and both short

sides). Then I turned it right side out so the camo is

facing out (which hides the 1/8-inch hems inside).

|

|

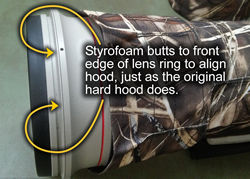

Styrofoam

strip butts to

lens ring for alignment |

|

|

3/16

inch thickness and 3/4 inch width

is sufficient for styrofoam strip |

|

|

Examples

of the shiny "plastic"

type styrofoam to use |

|

| Shelf

liner used on alignment strips |

Next

I marked lines 1-9/16 inches apart on the black ripstop

side to show where the stitching goes to form the pockets

for the slats. Be sure to leave extra material on both

short ends for overlapping where the velcro will hold

the ends together into a cylinder. Your measurements will

be different than mine, depending upon the lens you're

making it for. Then I slipped the 13 slats into the pockets

I just stitched. This first

assembly is shown in this photo. It's important the

pocket width is sized so the slats just slip in snuggly.

Second Assembly - Alignment Strip:

The

alignment strip fits around the lens ring and holds the

hood in place and properly aligned on the lens. I started

with a piece of black ripstop nylon long enough to wrap

around the lens ring, and wide enough to form two channels - one

for the styrofoam and one for gray foam strips, plus flaps on

both long sides to attach it to the hood slats assembly.

I found some "plastic"

type styrofoam (used for packing in a box of something

I'd bought recently). Be sure you do NOT use the brittle

type made for arranging artificial flowers (won't work

so well). The styrofoam

I found was 3/16-inch thick (just right for my

lens), so I cut 3 pieces 3/4-inch wide by 7 inches

long. End to end they would wrap around nicely. This will

be used to butt

against the lens ring where the hard hood hooks on.

If you don't have this type of styrofoam, use something

that is firm so it will butt against the lens ring and

hold it's shape, yet it must be flexible to wrap around.

If it's not so flexible, you can cut notches in it on

the inner face so it can wrap around the lens easily.

Also

needed is some dense gray foam (which I salvaged from

equipment box packing) to serve as the padded fitting

on the alignment strip to hold

the hood onto the lens. I also added a 2-inch

wide strip of black shelf liner (like I used in

my lens

sleeve project) over the foam strip to provide

some grip to the hood when it's strapped onto the

lens.

While

working on this project I discovered that it can get tricky

when working with circumferences. Inner and outer circumference

measurements will throw you off quickly. When the padded

alignment strip piece was wrapped onto the lens and butted

end to end, it fit just right. But when laid flat against

the hood slats piece, it came out about 3/4-inch short

of where the ends should have been on the slats piece.

I was surprised, since the slats are less than 1/16-inch

thick. I did not expect that much difference in the outer

circumference. Now I understand why the LensCoat and AquaTech

products were all curled up. It has to be made that way

because of the difference between the inner and outer

circumferences. So, I had to build that curl into my DIY

folding lens hood.

|

|

Finished

alignment strip with

shelf liner installed

|

How

the alignment strip fits

onto the lens ring |

|

|

Alignment

strip ready to attach

to hood slats assembly |

Alignment

strip has velcro flap added and

is attached with circumference adjustments |

|

Pinning

and sewing channel

for

styrofoam inserts |

|

Marking

and sewing channel

for foam inserts |

Fitting It Together:

The

necessary curl was built into the unit by stitching the

alignment strip assembly onto the hood stats assembly

with the slats puckered up about 3/16 inch at each stitching

point, as shown in this

photo. Your adjustment amount may be different, and

will take a little calculation. My alignment strip fit

was about 3/4 to 1 inch short of where it should line

up on the ends of the hood slats assembly. I divided that

by the number of sewing attachments points (the gap

between every other slat), which in my case was six.

That came out to about 3/16 inch per attachment point.

With my slats spacing at about 3-1/8 inch per 2 slats,

I placed sewing marks on the alignment strip assemby every

2-15/16 inch. This forced the slats to accordion a little

to make the sewing marks align with the gaps between slats,

providing the adjustment I needed. I realize it's difficult

to explain here, but looking at the

photos should help make it clearer.

Note

that the ends of the alignment strip are not sewn down.

On one end of the alignment strip I added velcro loops,

and the other end I added a flap with velcro hooks. This

velcro holds

the ends of the alignment strip together on the lens

and makes the hood fit snug, hold tightly and align properly.

With velcro added to the end flaps of the hood slats assembly,

it holds

the wrap-around overlap of the slats in position.

This completely hides all indications of any kind of mounting

straps, making for a very neat and professional-looking

hood.

|

|

|

|

Pull

alignment strip ends close together

and connect velcro flap |

Alignment

strip velcro flap is

closed, holding hood firmly |

Next,

fold over hood flaps connecting

velcro strips on hood |

Alignment

strip is completely hidden,

as are the hood's velcro strips |

|

|

| LensCoat

TravelHood |

AquaTech

Soft Hood |

|

| Original

Canon hard hood with camo cover. |

|

| The

new DIY folding hood |

The

new

DIY folding hood has no cumbersome straps and buckles,

or unsightly velcro strips on the outside like the LensCoat

and AquaTech products shown at left. In the photos at

right, compare the original

Canon hard hood with the new DIY folding hood. The

DIY folding hood really looks much neater and sleeker

than the commercial alternatives. The folding hood does

extend backward over the lens about an inch farther, making

it appear slightly longer. But the folding hood extends

in front of the lens the same distance as the original

hood. It is also the same diameter.

Not

only does this hood look better, it weighs only 7.9 oz.

The AquaTech Soft Hood for a 500mm lens weighs 12.9 oz.,

while the LensCoat small TravelHood for a 500mm lens weighs

7.2 oz. (just 1/2 oz. less than the homemade version).

I

was very pleased with how this project turned out. But

it looks so good, I'm afraid I'll forget it's not the

original hard hood and try to stand the lens on end on

the hood. That's the one caveat with these folding hoods,

although AquaTech does claim you can do that with their

hood. It's something to consider.

So, What About The Lens Cap?

|

|

|

left: Lens cap for hard hood

right: Lens cap for lens |

Inside

view of lens cap |

Outside

view of lens cap |

Yeah,

there is that issue of a lens cap, now that you realize

the one you used over the hard hood won't work over the

bare lens. The whole idea here was to be able to pack

the 500mm without the hard hood, but that's not a good

idea without a lens cap. DIY to the rescue once more.

After having previously made my own lens

cap for the hard hood, it wasn't that hard to make

one for the lens itself.

|

| New

lens cap and folding hood combo |

I

found a lid from a large plastic coffee can that fit the

lens diameter nicely. I also had a plastic lid from some

sugar cookies that came in a plastic bowl. The two lids

nestled together perfectly to form a base. Then with a

coping saw I cut three disks from 3/32-inch plywood and

sanded the edges nice and smooth. Two of the disks were

slightly smaller than the inside diameter of the lens.

These were glued together with wood glue and covered with

ripstop nylon. They just fit inside to insure centering

of the cap. The third disk was cut to the outside diameter

of the lens. Along with the plastic lids cupping the outside

of the lens, it insures the cap cannot get pushed into

the lens. With the lids sandwiched between the plywood

disks, I have an extremely strong and lightweight protective

cap. Next I covered the lens cap outside with a bit of

foam padding and some Cordura camo fabric to give it a

professional look. The final touch was to use 1/8-inch

bungee cord and a cord lock to snug up the cap on the

lens. It's small, light, and very strong, which makes

packing the lens in my backpack case so much simpler and

easier.

|

| |

|

|

|

|

|