|

|

|

|

Portable

Blind with seat for Wetlands/Marsh

|

I

really do like my Walkstool, and use it all the time when

shooting from a tripod set low for a low profile. However,

there were times when I wanted to set up on the edge of

a shallow marsh, and I knew my Walkstool, or any seat

with legs for that matter, would sink right into the muck.

|

| Marsh

Blind setup at Lake Mattamuskeet |

Then

one day, while watching Doug Gardner's Wild Photo Adventures

episode one - Waterfowl of Eastern North Carolina, I was

inspired with an idea for a solution. Doug talked about

using a mortar mixing tub as a floating equipment carrier.

After a little thought, I decided if I was going to tow

this thing along behind me anyway, why not take the idea

one or two steps farther? I could turn it into a portable

blind with comfortable seat that wouldn't sink into soft

wet marshy ground.

|

Finished

blind with canopy down,

showing seat folded down and up |

|

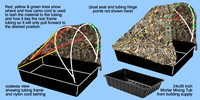

I

started with a 24x36-inch

plastic mortar mixing tub purchased for about $13

(available at most building supply stores). I already

had a very comfortable boat seat that I used on the ground,

but it only worked well if I was on the edge of a bank

or drop-off where my legs could hang down a little and

be a bit lower than my body. This folding seat was ideal

to mount inside the tub for seating.

|

Seat

mount assembly lifted

up to show details |

First

I cut a piece of 1/4-inch plywood to just fit inside the

bottom of the tub so it couldn't shift around. Next I

screwed and glued four 2x3 "posts" to the plywood base.

Then a 12-inch square piece of 5/8 plywood was screwed

and glued on top of the posts. This formed the seat

mounting platform. The posts were high enough to position

the seat just above the top edge of the tub. The seat

was then screwed to the 12"x12" plywood to complete the

seat assembly.

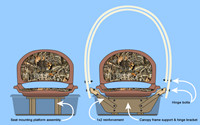

Then

I made a cardboard template to get the shape needed for

a bracket that would support the canopy frame. From the

template I cut out a piece of 5/8 plywood to make the

bracket, which screwed to the front seat posts under the

seat. The ends of the bracket curved up and out of the

tub. This gave me a place to hinge the canopy frame so

it can fold up or down. I glued and screwed a 1x2 to the

plywood bracket "ears" to reinforce the plywood where

the hinge bolt would go, which was rather narrow where

it curved up between the seat and the edge of the tub.

This also gave me a thick enough block to drill for the

bolt used as the hinge. Finding a suitable angle to drill

the bolt hole to hinge at the correct angle was the hardest

part of this project. Everything was at an odd angle because

the curved canopy frame pipe was not directly vertical,

but was angled slightly as shown in this

diagram. It took a bit of trial and error, and hole

reaming, to get the bind out of the hinge point.

|

Illustration

of seat mounting

platform and hinge bracket |

|

Illustration

of CPVC canopy

frame and canopy lashing |

I

made the canopy frame from two 10-foot lengths of 1/2-inch

(15mm) CPVC pipe, which is very flexible. (Do NOT try

to use 1/2-inch PVC. It is not flexible enough

for this. Be sure to get CPVC.) This was also

purchased at my local hardware supply. The front frame

loop of CPVC was cut 7' 5" long, which made a loop just

tall enough for my seated height. Depending upon how tall

you are, yours may have to be longer so your loop is tall

enough for you to sit under comfortably without hitting

your head. The back loop was cut shorter, only 6' 9" long,

as it hinges on the front frame loop above the front loop's

hinge and nestles just inside the larger front loop when

folded down so they both would lay flat.

The

canopy

frame was then covered with Hunter's Specialties Camo

Leaf Blind die-cut material in Advantage Max 4-D pattern

(the same as was used on several other projects on this

site). I used 1/8-inch nylon camo cord to lash the material

to the front canopy frame loop. I used more of the camo

cord to tie the back canopy frame loop to the rear of

the tub so the frame would only hinge forward as far as

needed. I wove the cord through the material die-cuts

to support the material, and lashed the material to the

back canopy frame with it as well. Once the front and

back canopy loops were lashed to the material, they were

held in place and worked in unison. Pulling up the front

canopy loop raised the whole canopy. Once raised, two

small bungy cords hold the front loop in place so it won't

flop back. Yet, if I forget to unhook the cord and try

to fold down the canopy, it won't break anything either,

because the bungy cord will stretch.

| The

completed unit is a breeze to use. Just flip up

the seat back, then flip up the canopy, hook the

two bungy cords and it's all ready to go. I takes

only seconds. |

|

Seat

mount assembly lifted up

to show hinge bracket |

|

Another

view of the canopy

frame

hinge bolts and bracket |

|

| Top down view of canopy frame hinges |

|

| Another detail of the hinge |

More

Photos:

These

photos show additional details. I have intentionally left

out most measurements, bolt sizes, etc. since this article

is meant to be only a starter for your version. For example,

you could make a seat from a plank covered with padding

and vinyl instead of using a boat seat. You could use

1/2-inch PVC with 45° elbows to make your canopy frame

instead of the flexible CPVC I used. Use your own creativity

to make something that suits your situation and needs.

Three

of these photos show different views of the canopy hinge

bolts. The black bungy cord is clipped onto the end of

the pipe for storage when the canopy is down.

The

lower left image shows the canopy frame up. The top end

of the bungy cord is hooked into a hole in the pipe and

the bottom end is hooked into a hole in the tub rim to

tension the frame in the up position. The second bungy

cord is only a spare, stored on the frame, in case a cord

breaks, or to supplement the tension in windy conditions.

You might notice that I covered some of the pipe with

a black material, but this is not really necessary. I

was experimenting with an idea. Usually I paint the pipe

frames I've used in these projects, or covered them with

camo tape, but you could just leave it the original color.

I'm not sure it matters, so long as it's underneath camo

material anyway.

In

these center photos ( below) I stuck my foot out so it

would be obvious there was a photographer inside. Otherwise,

you can't really tell. This blind, along with the lens

cover and tripod skirt, makes a very effective, comfortable,

compact and portable blind for marshy, wet environments.

The tub doubles as a gear carrier whether the canopy is

up or down. WIth the pull rope, the tub should glide easily

over grass and float on water, minimizing the amount of

weight you would otherwise need to carry by hand, or on

your back.

|

| Canopy

frame in up position |

|

|

| Side

view of blind with photographer, tripod and

super-telephoto. |

|

|

| Low

angle view of frame |

|

|

Detail

of cord lashing camo

material to frame |

|

|

| Angle

view of blind with tow rope |

|

|

| Angle

view of blind with photographer, tripod and super-telephoto |

|

|

| Detail

of storage area behind seat |

|

|

| Front

view |

|

|

| Despite

its compact size, the blind feels cozy without being

confining |

|

| |

Lightweight

Folding

One-man Blinds

|

There

is storage behind the seat to transport some gear - at

least a large backpack or dry-bag full. You can also use

bungy cords, hooked under the tub rim, to secure your

gear if it's stacked. With a little creativity, you can

make your own version of this combination "floating carrier/collapsing

blind/comfortable dry seat" for marshy ground. With the

addition of the matching camouflage lens

cover and tripod skirt, you have a highly effective

and complete camouflage blind that is very inexpensive

to make.

If

you're interested in some featherlight portable one-man

blinds, check out this article

for these two folding blinds pictured at right. |

| |

|

|

|

|

|