|

|

|

|

Boat

or Kayak Camouflage Cover -

Redesigned

|

When

I returned from the Merchants Mill pond trip, I resolved

to redesign the camouflage cover. After some thought,

I came up with what I feel is an even simpler cover frame

and a much more practical design. It eliminates the problem

of a wet cover dripping into the boat, gives easier access

to the front of the cockpit, and makes loading equipment

and myself even simpler. It will

also make it far easier to simply paddle the boat, on

those occasions when the trolling motor is not practical. I've

even added a simple way to attach branches and other natural

camouflage to the boat.

|

The

new concept - two simple hinged u-shaped

bars of pvc pipe

that fold up and down, like a convertible car top.

(click to enlarge)

|

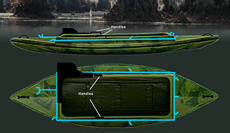

To

the right below are four diagrams. In diagram "1" the

turquoise lines show the basic pvc box frame which I retained

from the first cover design and reused here. The little

stubs sticking out around it represent short pvc pipes

that I added for attaching tufts of weeds and other natural

camouflage material, which I show later. The diagram also

indicates two handles I added so I have something to grab

onto when sitting down and getting up from the seat, which

is flat against the bottom of the boat.

1 1 |

3 3 |

2 2

|

4 4 |

| click

diagrams to enlarge |

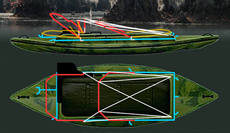

In

diagram "2" at right the red lines represent the "u-shaped"

sections of pvc pipe which hinge to move the front and

rear covers up or down. The yellow lines show the down

positions. The white "L's" are the hinges.

|

My

conceptual illustration of how the newly

designed cover would look (includes motor cover).

(click to enlarge) |

In

diagram "3" the white lines show the pattern for the nylon

cord used to hold the front hinged frame in place when

in the up position. The cord goes slack when the frame

is hinged down, but when it comes up the cord pulls taught

as the frame reaches the proper position. The cord also

serves as a support for the material covering the front

so it doesn't droop down into the cockpit. The front points

of the cord loop or tie to the eye hooks at the front

corners of the cockpit (see

this photo). The rear points of the cord hook

into the uprights of the rear frame by a small "S"

hook, and hold the front frame taught in the upright position

(see

this photo).

In

diagram "4" right above, the cream colored lines

show the cord pattern for the rear frame. The line stretching

forward on each side hooks into an "eye hook" to hold

the rear frame up in position. Unhooking the two lines

lets the frame hinge back and drop down.

|

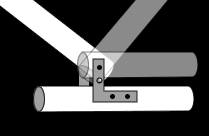

| Hinges

made from two "L" brackets |

I

was able to reuse much of the PVC pipe, pvc joints and

material from the first cover on the new frame construction

(because I used screws to secure the joints originally

instead of PVC cement). The hinges were made using "L"

brackets as shown in the diagram at left and the photos

below right.

In

the right bottom photo you can see how I used short pieces

of the foam insulation made for water pipe to pad around

the hinges. This insures the metal never rubs on the boat

fiberglass, and protects me from cuts and bumps on the

sharp end of a bolt or hinge corner when handling the

boat. Note the wooden dowel visible inside the pipe in

the right bottom photo. I used a 2-inch long section of

oak dowel, shaved down to just fit snuggly inside the

pipe, to reinforce where the hinge bolt goes through.

This prevents squeezing the pipe out of shape when snugging

up the nut and bolt. I recommend using a small washer

between the pipe and the "L" bracket to insure

it hinges smoothly.

I

no longer need the small bungee cords on each side to

hold the frame onto the boat. The base rectangle of the

frame is now held in place in the rear by the headrest

bracket, and in the front by two small pieces of oak at

the front corners (see left photo). I used the eye hook

bolt to hold the oak pieces in place. To remove the frame,

I only need to loosen the nut on the eye hook at each

front corner and turn the oak pieces to one side so the

frame will lift up and slide back from under the headrest

brackets.

The

camouflage material is attached very simply. It's tied

to the frame every foot or so with pieces of camo-color

nylon cord, the same cord used for the frame

supports. This is visible in the lower right of

this

photo. The photo also shows how the cord from

the rear frame hooks into the small eye hook to hold it

in the upright position as

mentioned earlier. The handles I added (mentioned

earlier) are visible in this photo as well.

The

left photo here shows two of the short pieces of PVC pipe

(I called them "stubs" earlier) which are located in strategic

places around the base frame. This is where I can attach

pieces of natural camouflage material. The lower left

photo shows three more of these "stubs" at the front of

the boat.

A

sample of what I mean by natural camouflage material is

shown in the photo

at right. I bundled some dried Pampas grass and

stuffed it into a short piece of 1/2-inch PVC pipe for

demonstration purposes. This one is obviously not finished

off. When finished, the grass would have more material

around the base to hide the bottom and give it a more

natural appearance. You can pre-make a few pieces to carry

with you, such as short dead brush limbs with spanish

moss draped over them, or perhaps short brush limbs with

leaves still present. Just shove them down into the pipe

for a tight fit.

This

method allows you the flexibility to add local vegetation

from wherever you are photographing so you can blend into

your current surroundings. The pipe stubs do not need

to be screwed or glued in, as they are sufficiently snug

enough to stay put. This permits turning the elbows on

the stubs to hold the material at the desired angle. The

stubs fit into "T" fittings situated around the base frame,

and can be removed or added as desired.

|

|

|

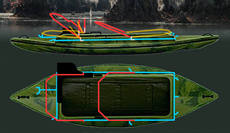

Fully

collapsed view - front and

rear covers are lowered. |

Rear

cover raised, front

cover hinged halfway. |

Front

and rear covers both

fully raised and hooked. |

To

the right are three photos of the completed design. It

does look a bit large sitting there in these photos without

a person in the pictures for comparison, but it really

is no larger than a 10-foot kayak.

|

| Interior

view |

|

|

| Front

angle views, fully covered and fully open. |

As

you can see, with both the front and rear covers collapsed,

I should have far less wind resistance when I'm trying

to load the boat onto the trailer. Secondly, I can climb

into the boat and load my gear just as easily as when

I had the old cover design hinged up into the air. I will

no longer have the problem of it then acting as a sail

in the wind. This is a far more elegant and practical

solution. Add to that the fact that I'm no longer raising

a wet, dripping cover fringe over my head and that messy

problem is solved as well. What goes in the water now

stays in the water.

The

"interior view" photo shows the headrest. It's

a bit hard to recognize since I made a slip cover for

it from the same material as the boat. This headrest can

fold down flat over the seat by simply removing one wing

nut, as shown in the below left photo.

One

more benefit of this new design is that it seems

I have more space for my equipment inside the boat than

I had with the earlier cover frame. The photo below left

shows how well I can see under the front cover now. The

earlier frame slanted down on either side from the center

"spine", which made it difficult to see underneath the

cover, or to reach my equipment bags.

|

Spacious

inside view

with the new cover design. |

|

|

The

seat & headrest

folded down. |

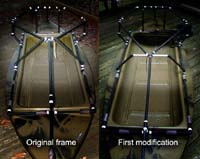

Two

versions of the

original frame

|

The

original frame is shown in the composite

photo at right. It came to a peak at the front

of the cockpit, which was a bit too high to easily take

photos over it. It was a simple modification to lower

the frame about six inches so I could see and photograph

over it more easily. The down side was that it became

even harder to see and reach up under the front cover.

The space inside the boat is so narrow (side to side)

that my bags had to be stored end to end between my knees.

However, the cover was so low I couldn't lift the equipment

bag in the front over the bag in the back to get to it.

This latest squared-off design gives me more room to see

under the cover and more height to access my equipment

bags much better than before. With the new design, if

I need to reach farther under the cover, I can simply

hinge the front cover up out of the way. Finally I had

a simple and practical design that could be adapted to

other boats. I hope the ideas in this article have provided

some incentive for you to try making a custom cover for

your boat.

|

| |

|

|

|

|

|