|

|

|

My

Native Ultimate 12 Tegris kayak is an "open" design, more like

a canoe than a conventional "cockpit" style kayak. It has no

deck of any kind, which is one of the reasons for the extreme

light weight of this kayak... a mere 29 pounds (without seat)...

truly a featherweight among kayaks. I knew I would need a center

skirt to shade my legs and feet from cooking in the summer sun.

The skirt would also minimize paddle drip on my camera equipment

sitting between my knees, right where most paddle drip would

end up. Though the manufacturer made bow and stern spray skirts

for this model, which I purchased, they never offered a center

skirt for it. It would be up to me to make my own center spray

skirt to provide shade and water protection.

|

|

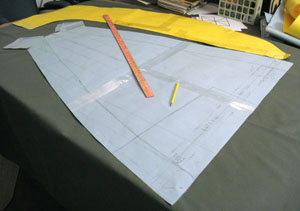

Two

views of the temporary cardboard batten.

|

After first

making a kayak cover for my Tegris from 500 Denier coated Cordura

nylon waterproof material, I turned my attention to making the

center spray skirt from more of the same material. I had already

drawn the skirt design on the computer, so I had a good idea

how the patterns should work (see

the cover article for drawings). However, without access

to a large format printer, the computer drawings of the skirt

design could not be used to print paper patterns for cutting

the material.

MAKING SPRAY SKIRT PATTERNS -

|

|

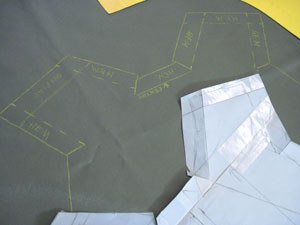

| Two

views of the paper patterns being fitted and marked. |

In order

to make paper patterns I had to resort to taping large sheets

of art paper together to make larger pieces to drape over the

kayak and create paper patterns by hand. For proper fit I needed

a temporary batten arch over which to form-fit the paper, so

I made one from corragated cardboard. With this temporary batten

wedged into place, I draped these larger pieces of paper over

the kayak, wrapping the paper around the gunwale (or gunnel)

and bow as if it was the material itself, and marked it with

a pencil.

Since the

bow piece was a symmetrical shape, I could fold the paper pattern

in half along the centerline and insure it was drawn and cut

perfectly symmetrical. The two side pieces should be mirror

images of each other, so I only needed to make one of them.

For the opposite side I simply used the same pattern but flipped

it over on its back side to use for marking and cutting of the

material. With the paper patterns now trimmed and marked with

my hems and folding lines I was ready to cut the material.

Having already

made a

"virtual" pattern layout on the computer, I knew how best

to arrange these life-sized paper patterns on the remaining

piece of Cordura material. I adjusted the arrangement for the

absolute least waste and pinned the paper cutouts to the material.

Next I traced them, adding my marks for hems, alignment lines

and arrows, and other notes right on the material. Then I cut

out the material pieces. (This only included the three main

pieces. The zippered flap would have to wait until I had the

main spray skirt assembled because the flap had to be fitted

to the spray skirt, not to the kayak itself.)

|

|

| Laying

out paper patterns on the material. |

Example

of tracing pattern onto material,

and adding hem marks and notations. |

I will note

here that you could alternately just lay the material over the

kayak, mark it and cut it out, much as I did with the kayak

cover. That worked fine for the cover because the shape was

quite simple (a large "football" shape), and it required the

full width of the material for the cover. There was simply no

need to "fit" a pattern to the material. Instead I had to fit

the material to the kayak. However, if I had done that with

the small complex and oddly shaped pieces of the center spray

skirt design, I could have ended up wasting a good deal of material.

I realized during the initial design drawing stage that it would

be best (and much more efficient) to make the center spray skirt

out of three main pieces (bow section and two long side pieces),

plus the zippered flap as the fourth piece. Making the paper

patterns allowed me to lay them on the material and arrange

them to best utilize the material without excess waste. This

proved particularly important with such oddly shaped pieces

as those for the center spray skirt. It also saved money on

material.

With the

skirt pieces cut and ready, I turned my attention to making

the battens before doing any sewing. If my batten idea didn't

work out, I didn't want to have to take out a lot of stitching

and make alterations to accomodate battens made a different

way. It would be easier to ensure the battens would work before

doing all that sewing.

MAKING BATTENS -

|

|

"Splitting"

1/2-inch CPVC pipe with

a hand saw. |

1/2-inch

CPVC pipe before and

after cutting in half. |

I had used both PVC and CPVC in previous projects for frames

and stiffening in camo blinds. I learned that CPVC was lighter

and more easily flexed and bent to shape. I had also learned

that heating CPVC with just a hair dryer (1500 watt or so) would

allow it to be bent easier, and hold the shape when cooled.

CPVC is waterproof, very lightweight, won't rust, will flex

and spring back, and is practically unbreakable - all good attributes

for batten material. An option would have been to use an aluminum

yard stick cut to size and bent into an arch, but I already

had sections of 1/2-inch CPVC on hand from those previous projects

and decided to try that first. Besides, if the aluminum was

accidentally bent, it would not spring back into the desired

shape by itself.

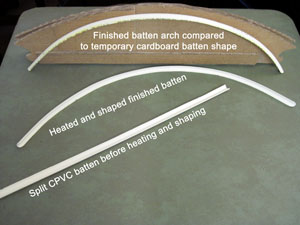

|

CPVC

battens comparead to the

temporary cardboard batten. |

In short

pieces, even the round 1/2-inch CPVC was too stiff to bend well

for what I would need here. Flatter material would fit inside

the channels in the material much better. So I put the CPVC

in a clamp and cut the 1/2-inch CPVC in half lengthwise with

a hand saw to get two half-round "slats". If you have a table

saw, splitting the CPVC would be even faster and easier. These

"slats" are relatively flat. It should be no surprise that these

flatter pieces flex more easily in short sections than round

pipe. Heating these "slats" with a hair dryer and shaping them

was much easier than doing so with round CPVC pipe. I found

that applying and holding the desired bend while heating them

works faster and better than heating a section and then doing

the bending. Heating it with the bend in place seems to "set"

the bend more quickly. Once shaped and cooled, they hold their

shape. Then when you try to straighten them, they spring back

into the bend you just put into them.

|

Best

way to shape CPVC battens.

|

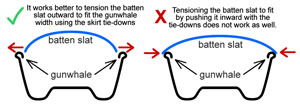

One important

thing I learned was that it worked better to pre-shape the battens

into a higher, rounder arch and less width between the ends

than you need. Then use the spray skirt tie-down points to pull

the ends outward toward the gunwale, slightly flattening the

batten's arch. This way the battens naturally want to return

to the higher arch by themselves, creating a firmer arch. The

alternative is to leave the battens straight, or only slightly

arched and wider than the gunwale, and then forcing them into

a tighter arch with tension against the gunwale using the spray

skirt tie-down points. Although that sort of worked, if the

tension slacked off, they would flatten out, which is exactly

the opposite effect from what you want to happen. It definetly

did not work as well as having too much bend and too little

width.

ASSEMBLING THE SPRAY SKIRT-

|

Inserting

CPVC battens into the channels.

Velcro flaps secure them inside the channel.

|

I knew sewing

together the three main pieces of the spray skirt would be a

slower process than sewing the relatively simple one-piece kayak

cover had been. There would be a bit of design-as-you-go involved,

since I didn't have all the answers just yet. I did have a lot

of ideas and possibilities I had considered at length during

the design drawing phase. However, I've learned from previous

projects that what I thought would work, and what would actually

work does not always coincide when doing projects like this

one. There is always a bit of learn-as-you-go involved. First

I sewed the three main pieces together, and made a test fit

on the kayak. So far, so good. I made minor trimming adjustments

to the two flaps that wrapped around the bow point, pinned the

flaps together and did the finished sewing and hems on that

small area. The skirt design depends on hanging the front over

the bow point and pulling the rest of the skirt back from that

anchor point to tension the whole skirt into shape. Next I sewed

the channel hem around the cockpit cutout area so I could insert

the nylon cord/bungee cord around it. This cord would hook the

rear points of the two sides into the rear thwart, and pull

everything into shape - at least that was the plan.

My original

plan called for 1/4-inch bungee cord all the way around the

inner "cockpit" opening. I found out that this allowed too much

springy "give" to hold the skirt as tight as I wanted. I tried

using 3/16 nylon cord around the "cockpit" with a foot or so

of bungee cord on each end to hook to the thwart bar. That worked

better, but even that much bungee was too springy. Then I tried

useing a 1-foot length of bungee cord in the middle (around

the curved front edge) of the cockpit and a length of 3/16 nylon

cord on each side. That was better still, though the large knots

necessary to connect the cord and bungee tended to get hung

in the notches of the curved center along the hem when tightening

the cord. Finally I moved the bungee section to one side away

from any notches in the hem, and that did the trick. This seemed

to give me the best tension (and stiffest sides) for the cockpit

opening.

I inserted

the batten in the channel where the bow section and side pieces

were sewn together, as in my original design, and did another

test fit on the kayak. To my relief, it worked pretty much as

planned. However, the tension pulled down the cover a bit too

much just behind the batten. It seemed the batten was some four

inches too far forward to do exactly as I had intended. I decided

to add a second batten just behind the first one. Such practical

impirical modifications are often the case in my projects. It

only required an additional channel for the second batten to

slide into. Because I had designed the pattern with enough material

overlap to allow room for a second batten channel, all I needed

to do was a row of stitching to create the channel. With a second

batten inserted, it did the trick. Now it worked as planned.

|

The

Adapt-A-Trak kit clips.

|

With that

important hurdle behind me, I checked to see if the attachment

points I'd chosen for the Adapt-a-Trak clips would be optimal

for tensioning the battens and holding the skirt edge in place.

It became obvious this too was going to require some impirical

modifications as I fit things together and found out just where

the tension points were really needed.

|

Reinforced

slot for skirt tie-down

clips in Adapt-A-Trak railing. |

The Adapt-A-Trak

Lashpoint kit from Native Watercraft was the only source I could

find to get clips to fit their proprietary rail connection system

on the sides of the Tegris. I cannot fathom why they don't sell

the clip strip material, since they make very few items that

use that connection system. Native kayak owners who want to

make items not provided by the manufacturer have little option

for do-it-yourself solutions without a means to attach to the

kayak. The Tegris in particular is a problem, as it does not

have the option of the "Groove" adapter system that comes on

the poly Ultimate models to attach accessories. In the instance

of spray skirts, the Adapt-A-Trak strip is the only logical

attachment point short of drilling holes in the Tegris hull.

The kit

comes with four "lashpoints", but as shown in the accompanying

photo, each of these lash points actually has two pieces - one

clip sewn to a 1-inch web strap, and one clip sewn to a 1-inch

D-ring and 1-inch ladderlock (also called a strap adjuster).

Thus I actually had eight "clips" available to hook into the

Adapt-A-Trak strip on the Tegris. I had planned only six attachment

points (three on each side) for the spray skirt, but at this

point it looked like I may need to use all eight clips.

Note that

my center spray skirt design works alone, with or without the

OEM bow or stern spray skirts from Native, although I am also

using both in conjunction with the center skirt. The OEM skirts

do not interfere with my design, so I can leave them on when

using the center skirt.

With all

the clip points still not firmed up, I finished hemming the

rest of the center skirt. Then I cut slots into the cover for

the first pair of clips that hook onto the Adapt-A-Trak rail

just below the double batten. I reinforced the openings where

the web straps feed through, and sewed on the straps and ladderlocks

for these two clips.

My next

step was to sew the two 26-inch nylon zippers to the base spray

skirt. Then I set up my temporary cardboard batten again so

I could cut and fit a paper pattern for the zippered flap. This

was the final piece to the puzzle to make everything work as

designed.

ZIPPERED FLAP with LAP SKIRT -

|

Paper

pattern for the zippered flap after

trial and error fitting and adjustments.

|

The zippered

flap would have a CPVC batten at the rear edge to support it,

replacing the temporary cardboard batten. The two 26-inch nylon

zippers will allow me to roll the flap up out of the way. This

will open up the center skirt much like a cockpit style kayak

to reach equipment and for ease of entry and exit. It will also

have what I am calling a "lap skirt" that will function as a

sort of "touring skirt". This will offer additional rain protection,

as well as extra coverage from excess paddle drip whenever I

engage in some serious paddling. The lap skirt will tuck away

into a pocket on the zippered flap when not needed.

Once again

I had to tape two large pieces of art paper together to get

a piece large enough for the flap pattern. I soon found my attempts

to position the paper on the kayak and mark it very frustrating,

even with the temporary batten in place. Eventually I resorted

to taking measurements from my scaled design diagram and transferring

them to the paper to create a pattern. I cut this pattern out

and did a test fit with the kayak. After several rounds of re-marking,

taping more paper around the edges and refitting, I finally

achieved a useable pattern, although it now looked more like

a patchwork quilt. Next I pinned the pattern to my material,

marked it and cut out the material for the flap. Then I hemmed

all around the flap and once again made a test fit. So far,

so good. After some more pinning, fitting and scratching my

head, I decided I would need a second batten near the front

of the flap. It didn't take long to make the additional batten.

Then I made and sewed on two channels for the battens, slid

both CPVC battens into these channels and did another test fit

after moving the cardboard batten out of the way.

|

The

paper pattern for

the "lap" skirt.

|

This time

the news was not good. The flap sagged far too much. The tension

I expected would keep it in position only pulled it down flatter,

even with the batten inserted. After so much work it was rather

disappointing. This was obviously going to require some rethinking.

There had to be more support at the rear batten, which it seemed

was only achievable by making a longer batten that reached wider

and closer to the gunwale for support on the ends. So, I moved

the existing rear batten and channel forward near the center

of the flap, then moved the front batten and channel farther

toward the front as well. I made a new longer rear batten and

channel. This new one would extend over the zippers instead

of ending next to them. I wasn't sure how easily I could work

the zippers in this configuration, but I had little choice.

|

|

| Lap

skirt pocket with skirt tucked inside. |

Lap

skirt deployed. |

When I tried

this new modification I was very pleased. I now had a workable

solution. With the skirt and flap installed on the Tegris, I

climbed in to be sure I had sufficient knee room. I found there

was more than enough room, and the batten height was just what

I was shooting for. To finalize this modification, I removed

the skirt and did the final sewing of the zippers to the flap.

After a little final stitching to permanently attach the front

edge of the flap, I was home free. There was still the "lap

skirt" piece to be made and attached, but that would be simple

enough. All the difficult work was finished.

For the

"lap" skirt I made another paper pattern by a combination of

measuring and test fitting. I traced the pattern onto the Cordura

I had left, cut it out and stitched the hems around the edges.

On the back edge where the skirt wraps around the body I made

the hem wide enough to form a channel. I will feed 1/8 or 3/16

bungee cord through this channel and clip it to the thwart bar.

That will hold it snug while still having enough stretch so

I can comfortably move and paddle. About twelve inches of the

front edge is sewn to the zippered flap. The rest hangs down

to shed water. On top of where it's sewn to the zippered flap

I stitched on a "pocket" where I can roll up the lap skirt and

store it out of the way when not in use. It will also make a

handy spot to temporarily stuff small items.

|

|

|

| Two

views of the nearly completed skirt. The "lap" skirt has

not yet been attached. |

A

full side view of the center skirt

before the "lap" skirt was added. |

|

|

|

Here

the zippered flap is unzipped

and rolled up out of the way. |

Alternately

the zippered flap can be

rolled under behind the footrests. |

The

fully completed center spray skirt

with "lap" skirt deployed. |

So, there

is the finished center spray skirt for my Tegris. I have taken

into consideration the idea of using a camouflage cover over

this skirt. It should be as simple as using some die-cut polypropylene

camo blind material, or even some netting in which I can stuff

natural vegetation. Either one can be draped over the skirt

and tied to the bow handle and the D-rings along the sides of

the skirts. The center skirt will hold it up out of my way.

Combined with some camo clothing it should work out nicely.

|

|

|

|

|